Odex drilling

Unexpected and unforeseen problems in drilling are inevitable and you can expect various types of obstructions in various types or methods of drilling such as churn drilling, percussion drilling, rotary drilling, and diamond drilling. You can even come up with drilling problems where there was no problem in the previous drilling. Similarly, two different wells adjacent to each other can result in different types of drilling problems due to different types of geological conditions.

In the context of numerous drilling-related complications, ODEX drilling is one of the latest and modern technological advancements that are popularly useful in underground drilling projects where obstructions are encountered or expected. ODEX is an abbreviation and it stands or represents “Overburden Drilling EXcentric.” ODEX is considered essential when the drilling faces rock strata or boulders and needs to penetrate densely.

Where does ODEX Drilling is Considered Necessary?

ODEX drilling is extremely useful and felt essential in drilling the following:

– While drilling through obstructions, rock strata, and boulders

– When installing permanent or temporary casing

– While drilling the rock-sockets

– While pre-drilling for the purpose of a Continuous Flight Auger (CFA) project

What is the Basic Technique Used in ODEX Drilling?

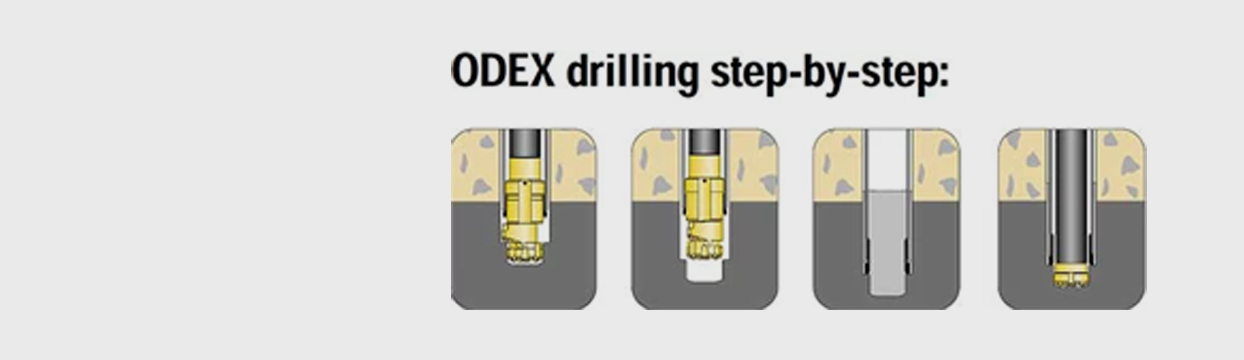

In the ODEX drilling, a drill string is systematically lowered into the outer casing or the steel tube. Eventually, this drill string is specialized and meant for heavy-duty performance. In the process of drilling, this drill bit instantly cuts with amazing speed. This is done much ahead of or prior to the steel casing resulting in the opening of several bit wings. Ultimately, the bit actively drills the hole that can be greater in diameter in a slight comparison to the steel casing.

In the process, the drill bit shoulder hits the shoe inside the casing resulting in simultaneous hammering on the steel casing near the back of the drill bit. This process discharges high-pressure air through the flushing holes. The air is discharged on the drill bit that eventually pushes the drill which arises the casing at the backup. Then the casing is caught up by a shroud ultimately discharging into a skip.

As the drill reaches the desired depth, the technicians turn the drill bit in reverse. This reverse process folds the wings withdrawing the drill in the casing. However, the casing is ultimately left where it is while withdrawing the drill. The next process involves the filling up of grout or concrete in the pile after placing a solid bar or reinforcement cage. The technicians may remove the casing tube or keep it permanently once the grouting or cementing is over.

The Advantages of ODEX Drilling

– The ODEX drilling can perform any type of overburden drilling without any deviation. Its bit design keeps the casing straight resulting in straight holes

– The ODEX can perform both concentric as well as hammer penetration. You can drill deeper designs with concentric design in comparison to other design whereas hammer the fractured rock or boulders

– The ODEX drilling is smoother in comparison to other technique which is harder than the ODEX drilling

– The ODEX is simple with minimum components in comparison to other techniques. For example, some designs have various components beginning from reamer bit, pilot bit, steel balls, spring pins, set screws, and many more that are usually expensive and not cost-effective to maintain

– The ODEX has strong and tough parts that are not fragile and do not break easily and eventually have less maintenance.

When the formation is unconsolidated or cobbly and dense for an auger drilling the ODEX is the best alternative with its system of sir hammering. The ODEX is designed with the latest and advanced techniques for easy and convenient performance of any type of overburden drilling. The ODEX has extremely higher penetration in rock formation and most convenient in high-risked caving formation which makes the ODEX special and the only one of its kind.