Start up hole in O and G

Getting into the industry in terms of investment or service providers is often an overwhelming thought due to the demand and profit opportunities. But the complex processes, metrics, and jargons used in the industry as well as the laws, regulations, and risks involved in every step of production to transportation, refinery, and distribution are not as easy as you think to grasp. This article gives you an overall understanding of how the industry runs.

What are the Basic Segments in the O&G Industry?

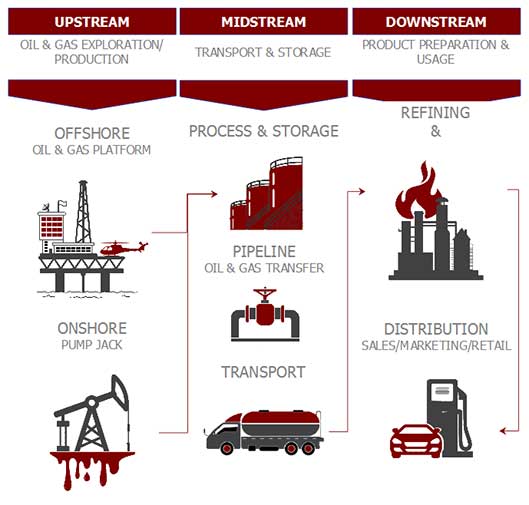

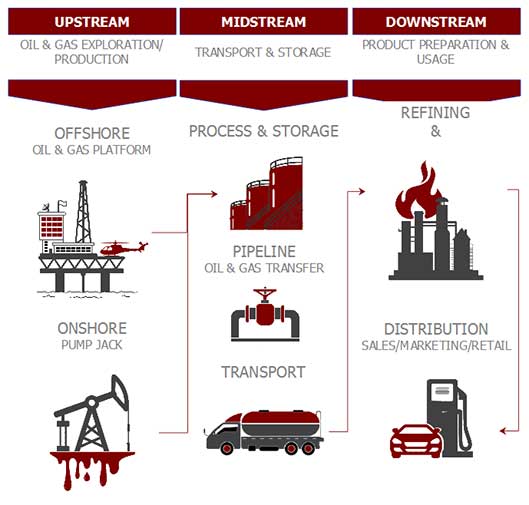

The O&G industry is primarily divided into three segments namely (1) the upstream segment, (2) the midstream segment, and (3) the downstream segment. These three divisions of segments are done basically as per their functions or stake-holding as follows:

Upstream Segment: The companies that are involved in the upstream segment of the O&G industry do the exploration and production of natural oil and gas resources. They constantly search for the O&G deposits or reservoirs and as they find an economically viable deposit of the natural resource, they extract the product. These companies are also known as “Exploration and Production” companies or “E&P” companies in the O&G industry. The E&G is considered as the primary stakeholders of the O&G industry because of technologically intensive characteristics, higher capital investments, unlimited and uncertain duration, and high risks.

Midstream Segment: The companies that provide transportation services of the extracted raw O&G resources to the refinery fall in the category of the midstream segment. The raw or crude oil and gas extracted from the under-rock deposits needs to be processed and refined to use for different purposes. So, they need to be moved to refineries through various means of transportations such as storing, trucking, shipping, through pipelines, etc. The midstream segment of the O&G industry does this job. Exactly like the upstream segment, the midstream segment also involves risks and laws and regulation-related restrictions, especially for pipeline transmission. However, the midstream segment is mostly dependent on the versatility and success of the upstream segment.

Downstream Segment: The refinery companies go under the downstream segment of the O&G industry. These companies remove the impurities from the extracted raw oil and gas and convert the crude product into various usable oil and gas products such as jet fuel, gasoline, asphalt, heating oil, etc.

What are the Conventional and Unconventional Methods of Drilling O&G?

The extraction of natural raw oil and gas from the under-rock deposit or reservoir is done by both conventional and unconventional methods of drilling. The upstream companies that follow the conventional method drill a well and follow the process of using the pressure of the reservoir which ultimately flows the oil and gas from the reservoir. But as the well gets older and the pressure of the reservoir becomes weaker the companies rely on a pump to extract the oil from the reservoir.

The unconventional method involves horizontal drilling and fracking to extract the oil and gas from the reservoir. The process of fracking ultimately opens the rock above the reservoir and increases the speed of oil and gas flow. Eventually, the unconventional drilling is expensive than the conventional method but provides more output in terms of quantity of extraction.

However, the conventional method and unconventional method are not competitors rather go hand in hand in oil and gas extraction. In most cases, the companies involved in gas and oil extraction start with conventional techniques and then use fracking to increase production. Though the conventional method is low-cost as the pressure decreases the technique necessarily requires horizontal drilling and fracking to increase productivity.

The Step by Step Systematic Extraction of Oil and Gas

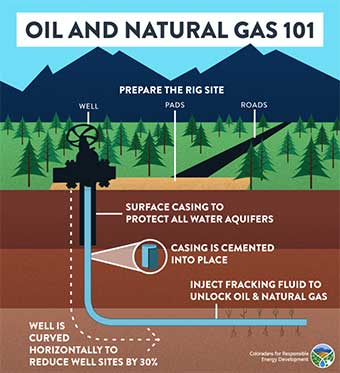

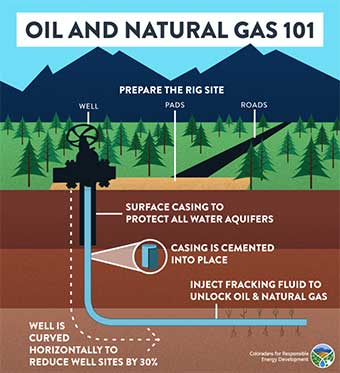

Step one: Once the upstream company completes the search of a viable O&G deposit it collects all the required permits and licenses prescribed in the state or country-specific laws, rules, and regulations. Then it starts with the infrastructure preparations such as access roads, pads, setting up the drilling land, security and safety measures, noise barriers, etc.

Step two: As the aboveground infrastructure is prepared, the next step is the making of infrastructure for drilling. The company brings the drill rig which may consist of 25 to 30 truckloads of equipment and other materials and put them together. Then a well is drilled under the pad as deeper as a mile. The first step of drilling is called the “start-up hole” or the “surface hole” which comprises up to 100 feet until reaching the deepest aquifer. Then a steel casing is done and cemented so that the groundwater or the aquifer does not get polluted.

Step three: The third step is the “long hole” that starts after the steel casing and continues drilling up to reaching the natural oil and gas. This drilling may go about the depth of 1000 feet or even more. In the process, the hole is steered horizontally and out which may comprise the drilling of a distance of a mile or two. Eventually, the process of drilling requires phenomenal technologies and expertise. However, some companies also use vertical drilling.

Step four: As the drilling is completed, the drill pipe is ultimately removed and the steel pipe is pushed to the entire hole. As usual like the surface hole, the long hole is then cemented which is called “well casing”. The steel pipe along with the well-casing undergoes a rigorous test to ensure their perfection and sustainability.

Step five: Before starting the process of extraction, a perforating gun is sent or lowered through the hole into the rock and fired into the rock. This eventually cracks the rock and opens holes in the rock to allow the gas and oil up into the pipe.

Step six: Now the trapped gas and oil under the rock which is mostly 99.5% sand and water and 0.5% chemical (fracking fluid) are extracted with specialized instruments that scientifically monitor data and pressure. The process continues until the fracking fluid is completed and completely drained.

Step seven: The extraction continues until the total length of the wellbore is fracked. The process may take up to 4 or 5 days to start production. As this process completes the oil and gas flow up from the wellbore.

The job does not end as the production of gas and oil starts by fracking. Eventually, the job of the midstream and downstream companies starts until the product is refined and sent to the market. The life span of an O&G well or a reservoir depends upon the deposit of the natural resource. It normally takes up to 20 to 30 years to empty a reservoir. Once the raw O&G is completely removed out of the reservoir the upstream company shuts the well by systematically filling the well. It also tests the soil for land contamination and produces a reclamation and remediated report. This report confirms that the site can be used for other purposes and thus the O&G extraction process ends at a specific location.